Elsecar Collieries comprised several pits, some started in the 18th century, on land owned by the Marquis of Rockingham and subsequently by the Earls Fitzwilliam in and around ElsecarFormer mining village in South Yorkshire, six miles north of Rotherham and six south of Barnsley., south of Barnsley on the Yorkshire Coalfield. Small-scale coal mining had taken place in the area since at least 1396.[1]

From the start of the Industrial Revolution, the Fitzwilliams amassed a vast fortune from coal. They were considered to be good employers, using the best technology available at the time to make working conditions safe, paying fair wages and providing decent housing.[2]

Old collieries

Elsecar Old Colliery (Elsecar High Pit) near Milton Hall was sunk to the 9-foot (3 m) thick Barnsley seam, 16½ yards (15.1 m) from the surface, in 1742 by Richard Bingley. The colliery had three air shafts and a winding shaft equipped with a horse ginHorse-driven engine used in lead and shallow coal mines. in 1752 when it was taken over by the Marquis of Rockingham. The Rockingham estates, including the collieries, were inherited by the 4th Earl Fitzwilliam in 1782.[1]

The earl supported the construction of the Elsecar branch of the Dove and Dearne Canal which was approved by an Act in 1793. At the same time he began to sink the the shafts of Elsecar New Colliery (Elsecar Middle Pit) and production started in 1795.[1] He installed a Newcomen-type beam engineSteam-driven Newcomen-type atmospheric pumping engine still in its original engine house at Elsecar near Barnsley. Designed by John Bargh of Chesterfield, the engine, is based on one invented by Thomas Newcomen in 1712. which was working by 1795 and remained in use until 1923.[2][3] The pit was ventilated by a furnace at the bottom of the upcast shaft and a third shaft was sunk for winding coal, initially by horse gin until another steam winding engine was installed in 1796. The Barnsley seam was 35½ yards (32.5 m) from the surface and 112 inches (284 cm) at the new pit. Its coal was supplied to the Elsecar Ironworks which opened the same year as the colliery. The canal arrived in Elsecar by 1804 and coal could then be transported from source. In 1808 the workforce was 95 men and boys.[4]

Jump Pit, an extension of New Elsecar, was sunk 60 yards (55 m) to the Barnsley seam in 1816.[4] The shaft at Jump was connected to the canal by an inclined plane in 1836, all the infrastructure, rails, wagons and engine were supplied by the Milton Ironworks.[5]

Two shafts for Hemingfield Colliery (Elsecar Low Colliery) were sunk close to the canal in 1840. A branch of the South Yorkshire, Doncaster and Goole Railway was built in close to it in 1850. The Barnsley seam, which dipped to the east, was reached at 153 yards (140 m). It was a gassy seam and the colliery was equipped with an underground steam-powered fan for ventilation. The pit produced 1000 tons of coal per day in 1848.[5]

An explosion of firedampDamps is a collective name given to all gases other than air found in coal mines in Great Britain. The chief pollutants are carbon dioxide and methane, known as blackdamp and firedamp respectively. killed ten men at Hemingfield in December 1852 when a ventilation door was left open and a miner removed the top of his lamp. Twelve others were injured.[5]

Simon Wood Colliery was started in 1852. The Barnsley seam was reached at 93 yards (85 m). The colliery was equipped with a steam-powered ventilating fan invented by Benjamin Biram, superintendent of the Fitzwilliam’s mines. Simon Wood had three shafts.[5] The pit closed in 1903.[6]

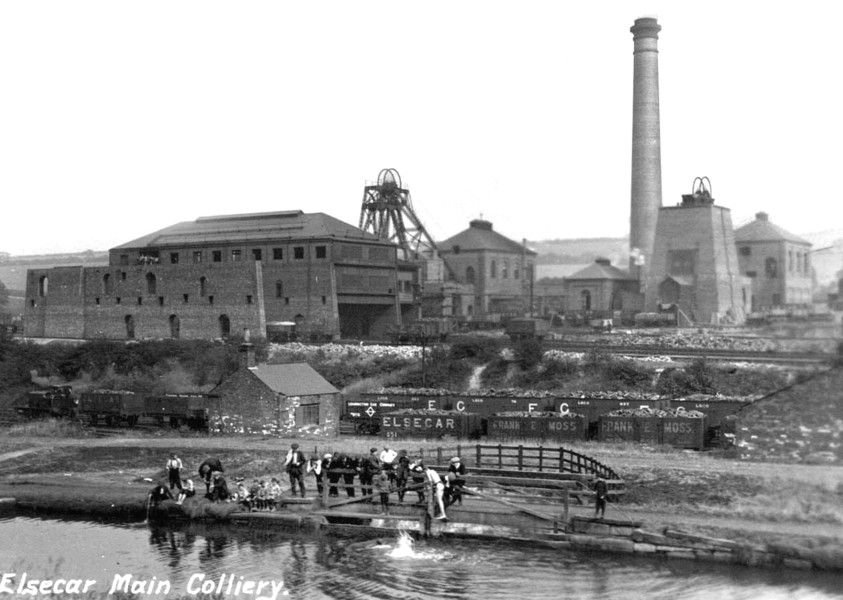

Elsecar Main Colliery

The 7th Earl decided to sink Elsecar Main in 1905 to work the Parkgate seam with a “take” covering 2880 acres (1,165 ha). No. 1 shaft was 16 feet (5 m) in diameter and reached the 54-inch (137 cm) Parkgate coal at 344 yards (315 m). No. 2 shaft was 18 feet (5 m) in diameter and 400 yards (366 m) to the sump bottom. Both were brick-lined and had Bradley and Craven winding engines. The colliery generated its own electricity using steam produced by ten Lancashire boilers. The boilerhouse had a 184-foot (26 m) high chimney. The Newcomen engine that continued to dewater the pits was replaced by electric pumps.[6] Over its lifetime Elsecar Main was further deepened to access the Silkstone seam at 534 yards (488 m) in 1945–1925. Electric coal cutters were used in the 33-inch (84 cm) seam.[6]

The Earl Fitzwilliam Collieries Company was incorporated in 1933. The 28-inch (71 cm) Thorncliffe seam was accessed in 1937 and a new ventilation fan was acquired. Pit head baths were built in 1938 when 1500 men were employed.[7] As the Parkgate seam became exhausted in 1942–1943, it was decided to drive a surface drift to the 52-inch (132 cm) Haigh Moor seam, which was 144 yards (132 m) beneath the surface.

The Fitzwilliam era ended in 1947 when the colliery was nationalised. In 1949 the pit employed 1760 workers. The National Coal BoardStatutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. invested in the colliery in the 1960s and its output was 1.3 million tons in 1967. The colliery closed in October 1983, and the surface plant was demolished in 1985.[8][9]