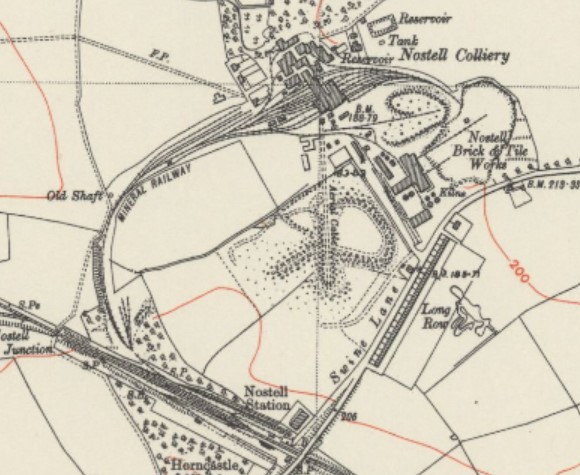

Nostell Colliery[1]

Reproduced with the permission of the National Library of Scotland.

Nostell Colliery on the South Yorkshire Coalfield was about four and a half miles (7.2 km) south-east of Wakefield, between Foulby and Wragby on the Nostell PrioryPalladian-style country house built near the site of a 12th-century Augustinian priory. estate. Coal was got at Nostell from the 9th century, and the industry was developed by the Winns of Nostell Priory from the 1700s.

The modern deep colliery was started in 1860 by the Winn family who still owned the estate.

History

Coal was dug from the outcropping Shafton seam in the 9th century in the area in which St James’ Hermitage was founded on what became the Nostell estate. The priory, founded in 1121, was granted permission to mine coal. When the outcropping coal was exhausted in the late 1300s, bell pits were sunk. The Winn family bought the 300-acre (121 ha) estate, which included coal mines, in 1654.[2] At first the Winns leased the coal rights to others and mining was on a very small scale, the small pits worked by a couple of miners.[3] In 1700, Wragby housed “9 Colliers along with other workers of the estate”. In 1742 the Winns bought more land with mineral rights from The Earl of Westmoreland[4] and by 1760 had installed a Newcomen engine to drain the workings.[2] In 1779 between five and fifteen men were employed in the collieries at any one time.[5] Profits for the year were £206. Shallow bell pits were superceded by two 27 yards (25 m) shafts to the Shafton seam in 1821. Fourteen such shafts were sunk on the estate. In 1865 when the new colliery was ready for production the 1821 shafts were filled and capped.[6]

The modern colliery was started in 1860 when two shafts were sunk. They were lined with bricks from Purston. One of the shafts was 10 feet (3 m) in diameter and the other 12.25 feet (3.73 m). They both had steam winding engines, pumping engines, headgear and cages. The pit was ventilated by mechanical fan and had a coal screening plant. The owners bought 72 sets of workmen’s tools and acquired six pit ponies.[7][8]

More than 26,000 tons of coal was raised from the new colliery in its first six months giving the Winns nearly £8,000 in profit from the pit that was now capable of producing 100,000 tons a year.[9]

A brickworks was opened at the colliery in 1875.[6] It was equipped with a Bradley and Craven brick press capable of producing 10,000 bricks per day.[7]

In 1901 the colliery employed 638 underground workers and 132 on the surface. They produced 200,000 tons of coal. The colliery rescue teamSpecialised job of rescuing miners and others who have become trapped or injured in underground mines because of accidents, roof falls or floods and disasters such as explosions caused by firedamp. was formed in 1917. In 1918 Nostell Colliery Company Limited was incorporated. The company was obliged to supply Nostell Priory with up to 1,000 tons of coal a year and free electricity.[7]

In 1923 the colliery used cutting machines and employed 641 men underground. In the 1930s a smokeless fuel plant opened. The colliery was nationalised in 1947 when 700 men were employed. The National Coal Board developed the colliery and opened up new seams when others were exhausted. A surface drift was driven to access the Sharlston Top, Low and Yard seams.[10]

Welfare

In 1860 the Winns started building the first ten terraced houses at Long Row. It was completed with 40 more terraced houses. The family was considered to be a generous employer, compensating victims of accidents and providing coffins for miners killed at work. In 1880 more houses were built at New Crofton, known as “Cribbins Lump”, they had no running water. The company built houses until 1926 but they were all demolished in 1983.[6]

Six cottages for officials were built in the colliery boundary.[8] The Winns built a school midway between Wragby and the new houses at Nostell for worker’s children in 1876.[6][9] Pit head baths, with no hot water, opened in 1932.[7] Hot water was provided by the NCB in 1955.[10]