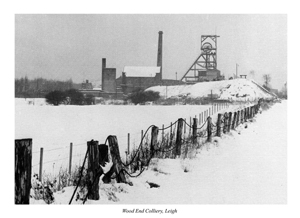

The Speakman family owned the Bedford Colliery from 1875 until it was amalgamated into Manchester CollieriesCoal mining company with headquarters in Walkden, Lancashire, formed in 1929 by the merger of a group of independent companies operating on the Manchester Coalfield. in 1929. Manchester Collieries was nationalised in 1947, and Bedford Colliery was closed twenty years later. John Speakman began sinking two shafts at Wood End Farm in Bedford, LeighSuburb of Leigh in Greater Manchester, one of the three ancient townships that merged in 1875 to form the town of Leigh. to the south of the Tyldesley Loopline in about 1875.

An explosion of firedampDamps is a collective name given to all gases other than air found in coal mines in Great Britain. The chief pollutants are carbon dioxide and methane, known as blackdamp and firedamp respectively. Damps is a collective name given to all gases other than air found in coal mines in Great Britain. The chief pollutants are carbon dioxide and methane, known as blackdamp and firedamp respectively. in one of the mines[a]In this part of Lancashire a coal seam is referred to as a mine and the coal mine as a colliery or pit. killed 38 men and boys on Friday 13 August 1886.

Geology

Bedford Colliery exploited the Middle Coal Measures on the edge of the Manchester CoalfieldPart of the Lancashire Coalfield. Some easily accessible seams were worked on a small scale from the Middle Ages, and extensively from the beginning of the Industrial Revolution until the last quarter of the 20th century. which were laid down in the Carboniferous period and where coal is mined from seams between the Worsley Four Foot and Arley mines. The seams generally dip towards the south and west and are affected by small faults. The Upper Coal Measures are not worked in this part of the coalfield.

History

Bedford was a rural community until the arrival of the Bridgewater Canal; a large basin built at Butts in 1795 proved to be a catalyst for the development of industry in the townshipDivision of an ecclesiastical parish that had civil functions.. Coal had been mined from small pits in the northeast of the township for many years. Wood End Farm was an area with many old small coal pits including Milner’s Pit which was working in 1853.[1][2] Coal provided the impetus for building the Tyldesley Loopline in 1864.

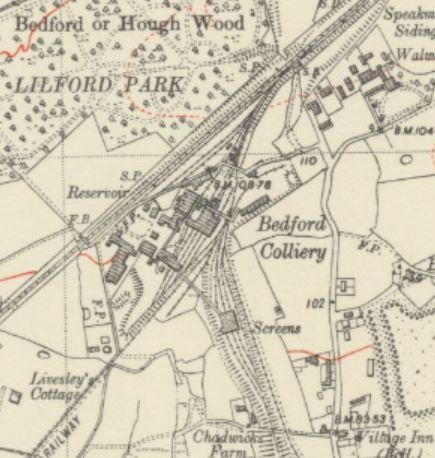

Reproduced with the permission of the National Library of Scotland

John Speakman of Bedford House began sinking two shafts to the south of the railway line in about 1875. The shafts were 30 yards (27 m) apart, the upcast furnace shaft was 15 feet (5 m) in diameter and the downcast 14 feet (4 m). Water was a problem during sinking and pumps were installed to remove it. At 297 yards (272 m) the Crombouke mine was reached and winding engines by Greenhalgh of Atherton were installed along with wooden head gear and double deck cages. In 1883 No. 2 shaft was deepened to 420 yards (384 m) to access the Seven Foot mine and later to 627 yards (573 m) to access the Trencherbone mine. Three years later No. 1 shaft was deepened to reach the Arley mine, at 891 yards (815 m).[4] The third shaft, 20 feet (6 m) in diameter to the Arley mine, was completed in 1909. It became the colliery’s main downcast ventilation shaft and was linked to the Arley and Yard mines worked by Chanters CollieryFormer colliery in Hindsford, Atherton where coal was mined from 1854 until 1966. after 1929.

Surface plant included six Lancashire boilers of which five were supplied by Musgraves of Bolton. They provided power for the winding engines, pumps and three endless rope haulage engines. Walkers of Wigan supplied an “Indestructible” fan and engine in 1894.[4]

Speakman’s Sidings between Tyldesley Station and Bedford Leigh Station were provided after 1882.[5] The company built a private mineral line about a half mile in length to Guest Street where they operated a landsale yard for local sales and from where coal was sent to Bedford Mill. The line also served a brickyard and smokeless fuel plant. The colliery was a major employer: in 1896 the colliery 366 men underground and 108 surface workers and in 1950 employed 772 underground and 221 on the surface. Household and manufacturing coal was initially won from the Crumbouke, Six Foot and Seven Foot mines and after 1948 from the Five Quarters and Victoria mines.[6]

After 1929 the colliery became part of Manchester Collieries.[7] Its railway was connected to the Astley and Tyldesley CollieriesColliery company formed in 1900, became part of Manchester Collieries in 1929, and some of its collieries were nationalised in 1947. railway system between NookCoal mine on the Manchester Coalfield after 1866 in Tyldesley, Lancashire, England. and Gin Pit CollieriesColliery that operated on the Lancashire Coalfield from the 1840s in Tyldesley Lancashire, England. . Manchester Collieries made improvements including new headgear and screens. The collieries were linked by an extensive system of mineral lines linked to workshops at Walkden Yard.[8] The colliery became part of the National Coal BoardStatutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. in 1947. It closed in 1967 with a loss of 518 underground and 131 surface jobs.[9]

Locomotives

The company bought a 0-6-0 saddle tank locomotive about which little is known; it may have been built by Andrew Barclay of Kilmarnock. This engine was replaced by a 4-coupled saddletank Sirdar from the Vulcan Foundry at Newton le Willows. In 1910 the company acquired Bedford, a 0-6-0 side tank built in 1865 by Manning Wardle of Leeds.[10]

Disaster

The Bedford Colliery disasterExplosion of firedamp on Friday 13 August 1886 which caused the deaths of 38 miners at Bedford No. 2 Pit in Leigh, on the Lancashire Coalfield. occurred on Friday 13 August 1886, when an explosion of firedampDamps is a collective name given to all gases other than air found in coal mines in Great Britain. The chief pollutants are carbon dioxide and methane, known as blackdamp and firedamp respectively. Damps is a collective name given to all gases other than air found in coal mines in Great Britain. The chief pollutants are carbon dioxide and methane, known as blackdamp and firedamp respectively. killed 38 men and boys. The event is marked by a memorial in Leigh Cemetery.[11][12]