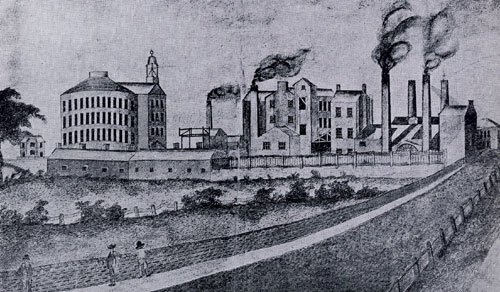

The Round Foundry was an engineering works off Water Lane in Holbeck, Leeds in Yorkshire, England. The complex was built for Fenton, Murray and Wood from 1795 to 1802 and was where they built beam engines and specialised textile machinery. Locomotives Salamanca, designed and built by Matthew Murray in 1812, was the world’s first commercially successful steam locomotive. for the Middleton Railway were built at the foundry which was named from the rotunda that was built in 1802 as a fitting shop and which burned down in 1873. The rotunda is marked by a cast steel inscription encircling its site. Several other buildings in the complex survive and are recognised by English Heritage for their historical importance. The run-down area is being regenerated and the buildings are now part of Holbeck Urban Village Media Centre.

History

The Round Foundry complex, one of first integrated engineering factories in the world,[1] was built between 1795 and 1802 by James Fenton, Matthew MurrayMatthew Murray was an engineer born in Newcastle on Tyne who became known for improving steam engines and building the first commercially successful steam locomotive., David Wood and the financier William Lister. It was at the foundry that Matthew Murray made his name as an engineer producing textile machinery, steam engines and the first locomotives for the Middleton Railway including Salamanca. The foundry housed one of the world’s first specialist engineering companies.[2] The rotunda from which the works was named was built in 1802 as a fitting shop. It was 81 feet in diameter, four storeys high, and powered by a 20 horsepower beam engine.[1] The rotunda was destroyed by fire in 1873. Some buildings on the site have survived, the earliest of which dates from 1795. Surviving buildings in the Round Foundry complex include the dry sand foundry,[3] the green sand foundry[4] which are Grade II* listed and Grade II listed, and 101, Water Lane.[2]

Intense rivalry between Matthew Murray and Boulton and Watt began when a representative from the Soho Works was shown round the foundry in 1799.[2] In an act of industrial espionage, a workman who had worked at Boulton and Watts’ Soho Foundry in Birmingham was persuaded to spy on Murray’s foundry. In 1802 James Watt jnr. described the foundry in a letter as 20 yards long and 12 yards wide. It had two air furnaces and three stoves, one 20 feet by 13 feet for loam, one 17 feet by 13 feet for boxes and one 17 feet by 9 feet for cores. A steam engine and boiler outside the south end was used for blowing the furnaces in this foundry in 1816.[3]

In 1811, a captured French privateer, was brought to the canal basin in Leeds where Murray fitted it with a steam engine and paddles to convert it into one of the first steam packet boats. In 1812 his works made two 4ft 1in gauge steam locomotives with a rack system designed by John BlenkinsopMining engineer at Charles Brandling’s Middleton Collieries who patented a rack and pinion system for a steam locomotive and commissioned the first practical railway locomotive from Fenton, Murray and Wood’s Round Foundry in Holbeck, Leeds in 1811. for the Middleton Coal Company. The Middleton Railway had obtained its act of Parliament and built the first iron rack railway from Leeds to its coal pits. The steam locomotives proved to be a success. George Stephenson saw the Murray locomotives in Leeds on others on Tyneside in 1813. His engines have many similarities to the Murray locomotives. The company suppied orders all over the world, including Sweden and Russia. After Murray’s death in 1826, his son-in-law took over.[2]

Surviving structures

The site of the Rotunda that burned down in 1873 is marked by a circular cast steel inscription on the ground marking the outline of where the building stood. It surrounds a pavement of stone setts.[5]

The Grade II* listed dry sand foundry, was built in about 1795 for Matthew Murray’s Foundry Street works. It was probably the earliest building on the site. It is a rare survival of an early workshop. Stone columns in the triple-arched entrance reflected the use of brick and stone in the White Cloth Hall of 1775Six cloth halls have been built in Leeds since 1711, and the remains of two survive. Four were for white cloth, one for mixed or coloured cloth and one for cloth made by unapprenticed clothiers. . It is a tall single-storey building of five bays built of brown brick. It has a hipped corrugated asbestos roof and tall two-flue chimney stack behind the ridge at the right gable end. Its facade on Foundry Street has tall arched multipane windows on either side of a central triple-arched entrance. The rear facade in the yard has arched three windows and a round-arched entrance supported by stone Tuscan columns. The frontage to Water Lane has a tall window and a lean-to extension.[3]

The brown brick building at 99, Water Lane is considered to be the remains of Murray’s green sand foundry. In 1802 it was described as containing two air furnaces and a cupolaSmall dome on top of a roof or other high structure.. Its four- bay, three-storey gable facing Water Lane has blocked taking in-doors and extends five tall bays and a two two-storey bay to the rear. It faces the dry sand foundry across the courtyard.[4] Between the two foundry buildings, 101 Water Lane was built in about 1800. It was considerably altered after the company closed in 1843, but a blocked cart entrance that accessed the courtyard indicates it was part of the complex.[2]

Regeneration

The run-down industrial buildings associated with the Round Foundry between David Street and Foundry Street on Water Lane were converted and refurbished between 2001 and 2004, marking the first stage of the Holbeck Urban Village project.[5]