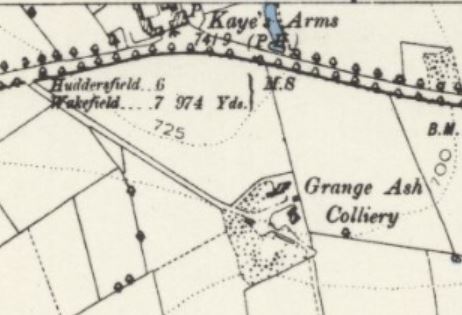

Grange Ash Colliery, 1894[1]

Reproduced with the permission of the National Library of Scotland

Grange Ash Colliery was sunk in fields to the north of FlocktonRural village stretched out along the Barnsley to Huddersfield road in Kirklees, West Yorkshire, taking its name from a Viking settler. village, just south of the Wakefield to Huddersfield Road (A642) between Caphouse CollieryEx-colliery in Overton, near Wakefield, West Yorkshire, now the National Coal Mining Museum for England. in Overton and Shuttle Eye CollieryColliery on the South Yorkshire Coalfield at Grange Moor in West Yorkshire, between Wakefield and Huddersfield on the A642 road. at Grange MoorA tract of moorland more than 700 feet above sea level gave its name to this Yorkshire village. crossroads. It was sunk by Jesse Jaggar on open land opposite the Kaye Arms Inn on land leased from the Lister Kaye family who had already worked the shallow Flockton Thin seam at 10 yards (9 m), and the Old Hards seam at 44 yards (40 m). Production from the New Hards seam started in 1871.[2]

Jaggar leased the mineral rights to the New Hards seam at 96 yards and sank two 12-foot (4 m) diameter shafts, both of which had pitch pine headstocks and steam winding engines. The coal was worked by pillar and stall methods. The voids were backfilled by hand, so that no spoil was wound to the surface. Single-deck cages each raised two eight-hundredweight (406 kgs) coal tubs, powered by four Lancashire steam boilers. The surface plant included blacksmith and fitting shops. Coal screens were erected near to the turnpike, connected to the colliery by a 200-yard (183 m) long tramway.[2]

The shafts were deepened to 150 yards (137 m) to the Blocking seam in the 1880s, and production started in 1887. A steam-driven ventilation fan was installed at the No.2 shaft and an underground endless-rope system was powered by a steam engine.[2]

Jaggar was the sole owner until he formed a partnership with Benjamin Elliott, a part-owner of Shuttle Eye Colliery by 1896. They employed sixty-five underground workers and seven on the surface.[3] The New Hards seam was worked out by 1916 and the Green Lane seam was developed and wound from No. 2 shaft.[2] The colliery employed 104 underground workers and 18 on the surface in 1919.[3] Pithead baths were built in 1935. The Wheatley Lime seam was developed after 1938.[2] Grange Ash had 168 men underground in 1945 and 25 surface workers.[3]

In 1947 Grange Ash was nationalised and became part of the National Coal Board (NCB). The colliery employed 195 workers (170 underground and 25 surface) who produced 70,000 tons of gas and steam coal.[3] The colliery had limited reserves but the NCB modernised what was possible. A conveyor belt carried coal to the screens, electricity replaced steam power and coal cutting was mechanised where possible. The NCB opened up the Beeston seam.[4]

In 1957, 186 men produced 88,622 tons of coal and in 1959, Grange Ash was connected underground to Emley Moor CollieryEmley Moor Colliery refers to several sinkings and drift mines over a large area of Emley, towards the television mast, between Flockton to the north and particularly towards Skelmanthorpe to the south. In 1964 the Beeston and Wheatley Lime seams were abandoned and the Blocking seam was approaching exhaustion. Half the workforce were transferred to other pits. The colliery closed in 1966 with the loss of 58 jobs. Surface demolition, shaft filling and capping took place in 1967 and the land was returned to agriculture; little evidence of the colliery remains.[4]