Reproduced with the permission of the National Library of Scotland

Thornhill Colliery had its beginnings in the 16th century when coal was worked at the outcrop on the hillside to the north of Thornhill Former township, now a suburb of Dewsbury in Kirkless, West Yorkshire. in the West Riding of Yorkshire. The Ingham family, who made their fortune from coal, began mining the shallow seams under their own land in Thornhill in about 1736. Their largest pits, CombsDeep coal pit in West Yorkshire, scene of a major explosion in 1839 that killed 139 men and boys working underground. and Ingham Collieries survived to be nationalised

Former township, now a suburb of Dewsbury in Kirkless, West Yorkshire. in the West Riding of Yorkshire. The Ingham family, who made their fortune from coal, began mining the shallow seams under their own land in Thornhill in about 1736. Their largest pits, CombsDeep coal pit in West Yorkshire, scene of a major explosion in 1839 that killed 139 men and boys working underground. and Ingham Collieries survived to be nationalised Statutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. in 1947 and were amalgamated in 1948 to form Thornhill Colliery, which closed in 1972.

Statutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. in 1947 and were amalgamated in 1948 to form Thornhill Colliery, which closed in 1972.

Early pits

Coal mined at the outcrop in the 15th century was mainly from the Flockton Thin seam, six yards (5.5 m) below the surface. The wealthy Ingham family of Mirfield owned land in Thornhill, and started coal pits on their own land in about 1736.[2]

Reproduced with the permission of the National Library of Scotland

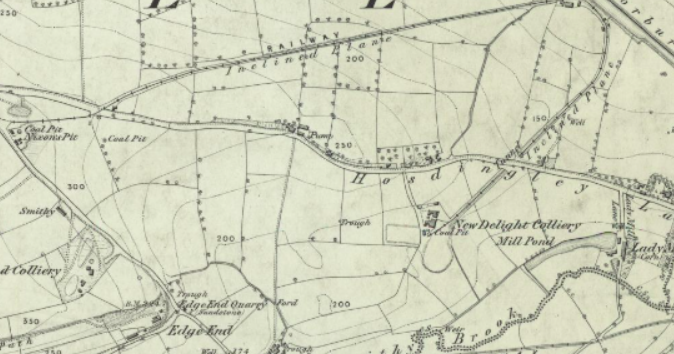

The Inghams had access to the Calder and Hebble Navigation Constructed between 1758 and 1834, the navigation makes the River Calder navigable between Sowerby Bridge and Wakefield in the West Riding of Yorkshire. by 1762 and leased land from the Saviles in 1782. Their early pits were close to the navigation. In 1802 Lees Colliery was working at Thornhill Lees and Park Colliery further east. Common and Mill Bank Pits were working near the navigation in 1825 and Cromwell Pit was sunk on the Lees Moor to the north of the village. It supplied coal to the company’s coke ovens that were built nearby and rope-hauled inclined planes linked the pit and coke ovens to the navigation at Mill Bank Wharf. Edge End Pit was sunk on Thornhill Edge close to Nixon’s Pit and New Delight Pit which were nearby with access to the navigation.[3]

Constructed between 1758 and 1834, the navigation makes the River Calder navigable between Sowerby Bridge and Wakefield in the West Riding of Yorkshire. by 1762 and leased land from the Saviles in 1782. Their early pits were close to the navigation. In 1802 Lees Colliery was working at Thornhill Lees and Park Colliery further east. Common and Mill Bank Pits were working near the navigation in 1825 and Cromwell Pit was sunk on the Lees Moor to the north of the village. It supplied coal to the company’s coke ovens that were built nearby and rope-hauled inclined planes linked the pit and coke ovens to the navigation at Mill Bank Wharf. Edge End Pit was sunk on Thornhill Edge close to Nixon’s Pit and New Delight Pit which were nearby with access to the navigation.[3]

The Inghams were major employers in the area. Before the 1842 Mines Act Act of the Parliament of the United Kingdom prohibiting all females and boys under ten years of age from working underground in coal mines. that prohibited children under ten from working underground became law, they employed 247 boys and girls in their pits.[3]

Act of the Parliament of the United Kingdom prohibiting all females and boys under ten years of age from working underground in coal mines. that prohibited children under ten from working underground became law, they employed 247 boys and girls in their pits.[3]

Deep pits

Between 1855 and 1857 the Inghams sank Combs CollieryDeep coal pit in West Yorkshire, scene of a major explosion in 1839 that killed 139 men and boys working underground., a deep pit, on land leased from the Saviles to the north of Hall Lane. By 1872 the Inghams had a workforce of 360 men and boys. In 1875 Ingham Colliery was sunk close to the old Cromwell Pit to the north of the village on Lees Moor. [3] Inghams Thornhill Collieries Ltd. was incorporated in 1898.[4] In 1911 the company workforce was 987 men and boys. Although the collieries were later joined underground, they were worked separately.[5]

The company leased land at Whitley UpperTownship in the ancient parish of Kirkheaton, in the West Riding of Yorkshire., Whitley Lower Village near Thornhill in Kirklees, West Yorkshire. and Sitlington

Village near Thornhill in Kirklees, West Yorkshire. and Sitlington Ancient township of four villages, renamed from Shitlington to Sitlington in 1929. from George Armytage of Kirklees Hall in 1918. The Beeston coal was sub-let to Lockwood and Elliot at Shuttle EyeColliery on the South Yorkshire Coalfield at Grange Moor in West Yorkshire, between Wakefield and Huddersfield on the A642 road. and New Hards were let to the Jaggar Brothers at Howroyd CollieryName for a number of day holes and drifts that worked the coal at the outcrop. in 1930.[5]

Ancient township of four villages, renamed from Shitlington to Sitlington in 1929. from George Armytage of Kirklees Hall in 1918. The Beeston coal was sub-let to Lockwood and Elliot at Shuttle EyeColliery on the South Yorkshire Coalfield at Grange Moor in West Yorkshire, between Wakefield and Huddersfield on the A642 road. and New Hards were let to the Jaggar Brothers at Howroyd CollieryName for a number of day holes and drifts that worked the coal at the outcrop. in 1930.[5]

National Coal Board

At nationalisation on 1 January 1947, the Combs and Ingham Collieries became part of the National Coal Board Statutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946.. At that time, Ingham No 1 produced 180 tons of coal from the Black Bed and Blocking seams per day, No 2 pit produced 450 tons from the Beeston and Wheatley Lime seams and Combs produced 140 tons from the Black Bed and Wheatley Lime seams. Most of the coal went to the colliery’s own coking plant, which was also nationalised.[5]

Statutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946.. At that time, Ingham No 1 produced 180 tons of coal from the Black Bed and Blocking seams per day, No 2 pit produced 450 tons from the Beeston and Wheatley Lime seams and Combs produced 140 tons from the Black Bed and Wheatley Lime seams. Most of the coal went to the colliery’s own coking plant, which was also nationalised.[5]

In 1948 the NCB combined the two pits, which were already linked underground for ventilation into Thornhill Colliery, and began a programme of reconstruction and modernisation which was complete by the end of 1957. A new shaft was sunk at Combs with steel headgear and a new winding house for its electric winding engine. A modern underground haulage system was installed and the colliery was electrified. Pit head baths were provided as part of the reconstruction. Output reached 233,000 tons per annum.[6]

The colliery’s coking plants closed in 1958 and a new drift was driven to access new reserves in the Wheatley Lime seam at Combs and work in the New Hards seam restarted. After 1946 cutting machines were used and coal ploughs were introduced in 1968.[6]

The NCB planned to link Old Roundwood, Shaw Cross and Thornhill Collieries in 1958. Thornhill was connected to Shaw Cross Colliery by 1960, and coal was all wound at Shaw Cross. Old Roundwood closed in 1966, and the connection was never made. In 1967 the colliery had a workforce of 413 underground and 73 surface workers. Shaw Cross Colliery closed in 1968 and the Thornhill and Shaw Cross reserves were worked by The Thornhill Combined Mine. In 1969 Thornhill employed 370 men and produced 230,000 tons of coal from the Beeston seam. Thornhill Colliery closed in 1972 as a result of the changing economic climate and diminishing reserves.[6]