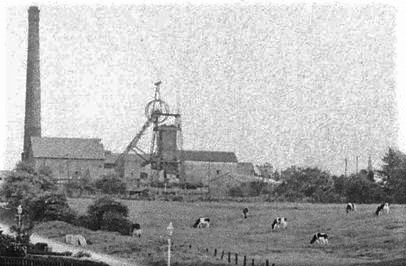

Chanters Colliery in Hindsford, Atherton on the Manchester CoalfieldPart of the Lancashire Coalfield. Some easily accessible seams were worked on a small scale from the Middle Ages, and extensively from the beginning of the Industrial Revolution until the last quarter of the 20th century. was started when John Fletcher sank a single shaft in 1854, in an area where coal had been mined for hundreds of years. It was developed by Fletcher, Burrows & CompanyOwner of collieries and cotton mills in Atherton in North West England. after 1872, Manchester CollieriesCoal mining company with headquarters in Walkden, Lancashire, formed in 1929 by the merger of a group of independent companies operating on the Manchester Coalfield. after 1929, and the National Coal BoardStatutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. . As the colliery developed two more shafts were sunk and over time were deepened to the Arley mine, giving access to twelve workable seams. Chanters Colliery closed in 1966.

Geology

Chanters was situated on the Middle Coal Measures of the Manchester CoalfieldPart of the Lancashire Coalfield. Some easily accessible seams were worked on a small scale from the Middle Ages, and extensively from the beginning of the Industrial Revolution until the last quarter of the 20th century. that were laid down in the Carboniferous period. The colliery had access to twelve workable seams between the Crumbouke and Arley mines.[a]In this part of Lancashire a coal seam is referred to as a mine and the coal mine as a colliery or pit The seams generally dip towards the south and west and are affected by small faults; the Upper Coal Measures were not worked in this part of the Lancashire Coalfield. Two coal seams outcropped close to the colliery: the Rams mine in the valley to the north; and the Brassey near Chanters Brook, close to the old Chanters Pit shaft.[1]

History

Coal had been mined in Hindsford for centuries from shallow ladder pits. One pit worked before 1800, the Gold Pit was named from the 17th-century coins and plates that were found at the bottom of its shaft. The deep pits were started by John Fletcher, who sank a shaft in 1854.[2] A twin-cylinder horizontal winding engine and a single-cylinder pumping engine manufactured by John Musgrave & Sons were installed in 1861. Steam for the colliery was supplied by three Lancashire boilers, the smoke from which was funneled through a 122-foot (37 m) tall chimney.[2]

During Fletcher BurrowOwner of collieries and cotton mills in Atherton in North West England.s’ ownership the colliery was modernised after 1891, when a second shaft was sunk to the Trencherbone mine at 1121 feet (342 m). The shafts were deepened to the Arley mine at 1832 feet (558 m) in 1896, both accessing twelve workable coal seams. [3] No. 2 Pit, the upcast shaft, had a ventilation furnace at the shaft bottom. A twin-cylinder horizontal underground haulage engine with 20×48 inch (51×122 cm) cylinders by Greenhalgh & Company from their New Foundry in Atherton was installed near the top of No. 2 pit in 1888; its ropes passed down the shaft guided by sheave pulleys. Two 7-foot (2 m) diameter winding drums and an 11-foot (3 m) brake drum were fitted. Steam was supplied by four Cornish boilers.[2]

More development took place in 1904, when the boilers and winding engine at No. 1 shaft were replaced,[2] and lattice steel headgear was installed. Coal screens and a coal washery were built at the same time. In 1926 the wooden headgear of No. 2 pit was replaced by Naylors of Golborne,[4] and the colliery subsequently continued to be developed and modernised until its closure in 1966.[3]

The colliery’s training gallery was used by recruits from most of Manchester CollieriesCoal mining company with headquarters in Walkden, Lancashire, formed in 1929 by the merger of a group of independent companies operating on the Manchester Coalfield. ‘ pits; 132 Bevin boys were trained at the colliery during the Second World War.[5]