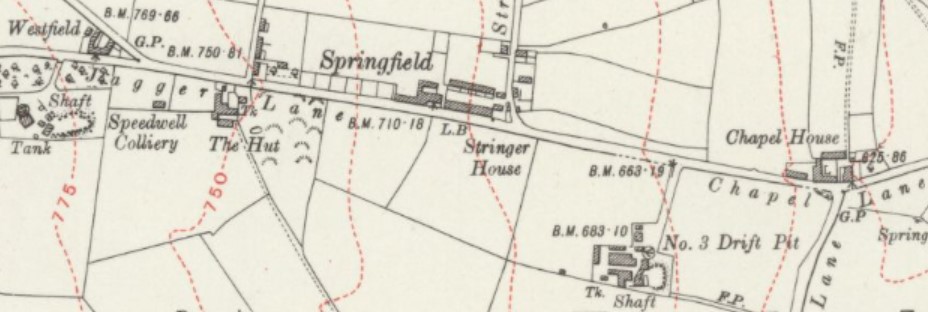

Emley Moor Colliery sites on Jaggar Lane 1930.[1]

Reproduced with the permission of the National Library of Scotland.

Coal mining around Emley in West Yorkshire has a long and complicated history from medieval times until the last colliery closed in December 1985. Emley Moor Colliery refers to several sinkings and drift mines over a large area of Emley, towards the television mast, between FlocktonRural village stretched out along the Barnsley to Huddersfield road in Kirklees, West Yorkshire, taking its name from a Viking settler. to the north and particularly towards Skelmanthorpe to the south. Coal was extracted from a widespread area around Emley village. The colliery was a major employer in the area and survived to be nationalised in 1947 and closed in 1985.

Geography and geology

Emley Moor occupies high ground to the west of Emley village in the South Pennines. No major roads or railways pass through the village which is approximately midway between Huddersfield and Wakefield.

The underlying geology comprises the Lower Coal Measures and sandstones of the exposed area of the South Yorkshire Coalfield. Tankersley ironstoneNamed from its outcrop at Tankersley near Barnsley in South Yorkshire. occurs as thin seams and nodules of siderite in the mudstone above the Flockton Thick coal seam.[2]

History

Evidence of small-scale medieval coal mining is found at the scheduled monument, Emley Day Holes, on the steep, scarp slope overlooking the Dearne Valley just to the south of Emley village. The various earthworks are where coal was mined from outcrops for use in iron forging. Drift mines were tunnelled into the hillside and spoil was deposited outside, building up level platforms along the hillside. These day holes are close to Bentley GrangeShaft mounds and earthworks south of Bentley Grange Farm are the remains of a medieval iron mining site between Emley and West Bretton in West Yorkshire. where the Tankersley ironstone bed was mined from bell pits.[3]

Coal was worked on Emley Moor in 1597 and from shallow shafts during the 17th century. The “Silver Pits” were recorded on a plan dated 1715. James Milnes who operated the Flockton CollieriesFlockton Collieries comprised several pits, some started before 1700, around Flockton and Middlestown between Wakefield and Huddersfield in the West Riding of Yorkshire. owned coal pits on Emley Moor accessing the New Hards seam in the 1780s and Emley had four coal pits by 1822. John Bedford owned one and three belonged to the Jaggar family who became the pre-eminent coal owners in Emley.[4]

The Jaggars sank a pit close to where the Emley Moor television mast stands in 1819. It accessed the Wheatley Lime seam and ten years later worked the Blocking seam. The underground workings were extensive, stretching north towards Flockton and east towards the Speedwell Fault. Other shafts were sunk, some more than 100 yards deep, as the workings extended away from the original shaft. The coal was worked until 1881.[4]

The Jaggars sank Park Pit to the Wheatley Lime seam south of Emley village in 1864. Water was a problem in the 61 feet deep shaft and the Benny Lane adit to dewater it was driven towards the north-west. Numbered ventilation shafts were sunk to the drift and No.2 Drift Pit was subsequently renamed Speedwell No.2 or Benny Lane Pit. No.3 Drift Pit became Emley Moor No.3 shaft and survived to be nationalised in 1947. When the adit was completed, water from the pits drained in to the River Dearne. Speedwell No.1 Pit’s two shafts were sunk in 1874 to access the Wheatley Lime and New Hards coal.[4]

The Jaggars opened Five Clogs Drift south of the village to access the coal via day holes in 1886. It was rumoured to have been driven by five men, one of whom had a wooden leg, hence five clogs. It was connected to Skelmanthorpe by a drift in 1892. The drift allowed all coal to be brought to the surface at Skelmanthorpe where it was screened for transport by rail.[5] The Lancashire and Yorkshire Railway had opened its Clayton West Branch through Skelmanthorpe in September 1879.[4]

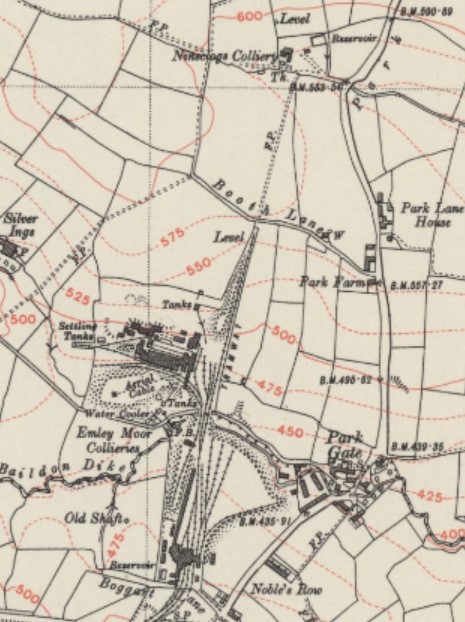

Emley Moor Colliery sites at Skelmanthorpe 1949.[6]

Reproduced with the permission of the National Library of Scotland.

The Jaggers opened Five Clogs Drift to access the coal via day holes in 1886. It was rumoured to have been driven by five men, one of whom had a wooden leg, hence five clogs. It was connected to Skelmanthorpe by a drift in 1892. The colliery was developed further and the pits interconnected so that coal from Emley No.3 could also be transported underground to Park Gate at Skelmanthorpe. By 1896 the pits employed more than 350 men and boys.[5]

In 1900 the Jaggar’s Emley Moor Collieries were amagamated with Stringer & Son’s Park Mill Colliery at Clayton West and a new company was created, Stringer & Jaggar. More development occurred and a coking plant was built at Park Gate. Two drifts and a shaft were constructed at Emley No.3.[5] Mechanisation was introduced in the form of conveyors. Speedwell No.2 Pit was sunk in 1910 and its ventilation shaft was one sunk before 1800 by James Milnes near Park Pit. By this time Emley Drift Pit employed 660 underground and 173 surface workers.[5]

The Jaggar family ended their mining ties in 1912 and Stringer and Son took over. Deeper seams were worked including the Blocking seam under Emley village. Drifts were driven towards the old Lane End CollieryFlockton Collieries comprised several pits, some started before 1700, around Flockton and Middlestown between Wakefield and Huddersfield in the West Riding of Yorkshire.. Some older reserves were worked out by 1920.[7] Flooding caused by an inundation from Lane End occurred at Speedwell No.2 Pit in 1923.[8]

During the 1920s coal was worked towards Shuttle EyeColliery on the South Yorkshire Coalfield at Grange Moor in West Yorkshire, between Wakefield and Huddersfield on the A642 road. and Grange AshColliery that operated between 1871 and 1966, south of the A642 road east of Grange Moor crossroads. Collieries. In 1934 the screens at Skelmanthorpe were enlarged. Speedwell No.2 closed in 1937 but its drainage system was kept open. The Beeston seam was worked from 1937 to 1945. When the colliery was nationalised in 1947 550 men were working at the colliery. It became part of the NCB North Eastern No.6 Barnsley Area.[8]

An electric fan installed at Speedwell Pit in 1953 had insufficient capacity to ventilate the entire workings and coal faces in the New Hards seam were closed. A haulage adit was opened at Nineclogs to allow materials to be taken underground. Lane End Pit was dewatered in 1956 allowing reserves of coal to the north-east to be accessed and in 1959 a connection was made to the Grange Ash workings to improve drainage.[9]

Coal tubs were replaced by underground conveyors from the coal faces to Skelmanthorpe and an electric winding engine in was installed at Emley No.3 shaft for winding men and materials in 1963. In 1967 the colliery employed 290 men who produced 121,000 tons of coal from the Blocking and Beeston seams. Emley Moor was grouped with CaphouseEx-colliery in Overton, near Wakefield, West Yorkshire, now the National Coal Mining Museum for England., Grange Ash, Howroyd, Lepton Moor, Park Mill and Shuttle Eye Collieries in 1972.[9]

More underground developments took place in the 1970s when the Beeston seam was most productive and in 1978, 319 men produced 100,000 tons of coal. The Beeston coal was exhausted in 1983 and the Whinmoor seam, less than 30 inches thick, was then worked by hand filling methods. The Skelmanthorpe washery closed and coal was washed at Woolley Colliery.[10]

Production was halted temporarily during the 1985-85 Miners’ Strike and ceased entirely in December 1985. The sites were cleared and shafts were capped.[10]