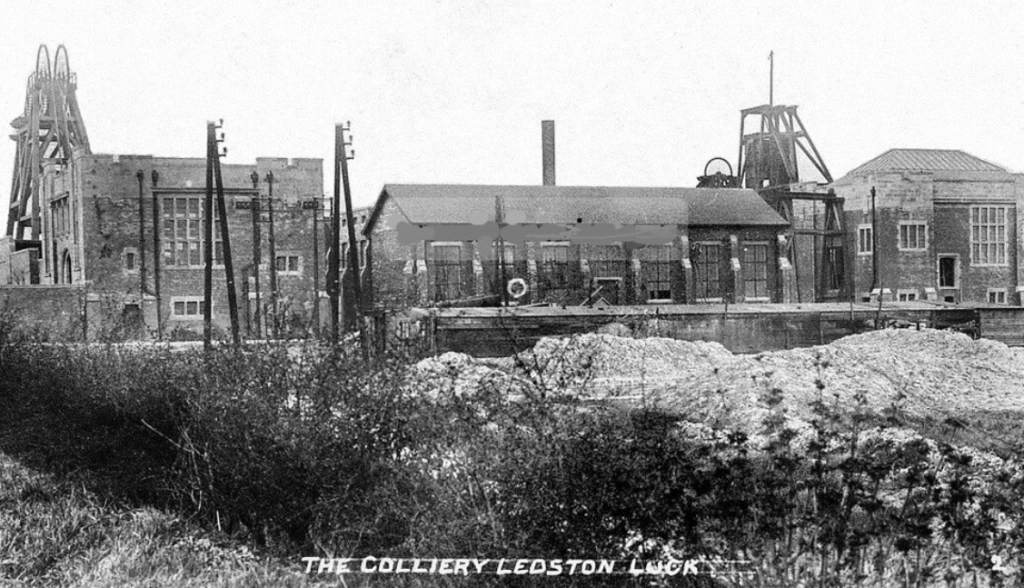

Ledston Luck Colliery, nine miles (14 km) east of Leeds and three miles (5 km) north of Castleford on the Roman Ridge Road, was sunk after coal had been proved under the Ledston Hall

Grade I listed former country house in West Yorkshire, now divided into residences. Estate in 1909.

The Micklefield Coal & Lime Company sank two shafts for the new colliery and by 1915 was producing coal from three seams. The colliery was mothballed during the Second World War and reopened by the National Coal Board, who proved coal in deeper seams; after extensive renovation, production resumed in 1950. Ledston Luck closed in 1986. The winding houses were preserved and listed by English Heritage.[1] Part of the site is now a nature reserve.

Geology

Ledston Luck Colliery was situated on the Yorkshire Coalfield, nine miles east of Leeds and two miles north of Castleford, where the Carboniferous sandstones of the Coal Measures are overlain by the younger Permian rocks of the Magnesian Limestone.[2]

History

The Micklefield Coal & Lime Company, owners of Peckfield Colliery, leased the coal under the Ledston estate from the owner, G. Wheler, with the intention of raising the coal at Peckfield, a mile and a half (2.4 km) to the north.[3] Intentions changed, and it was decided to sink a new colliery with two shafts with access to three coal seams next to the Ridge Road. Shaft sinking began in 1909, the first sod cut by Lady Wheler who declared, “I wish Little Ledston luck in their adventure”, and so the colliery was named Ledston Luck.

The Micklefield Coal & Lime Company sank two shafts for the new colliery, and by 1915 was producing coal from three seams. The colliery was mothballed during the Second World War and reopened by the National Coal Board, who proved coal in deeper seams; after extensive renovation, production resumed in 1950. Ledston Luck closed in 1986. The winding houses were preserved and listed by English Heritage.[1] Part of the site is now a nature reserve.

The No1 downcast shaft was 18 feet (5 m) in diameter, and reached a sump below the Beeston seam. Water encountered during sinking required a large pump. The shaft was completed in 1911 and was connected to Peckfield in 1913, where coal from the Beeston seam was extracted. The No 2 upcast shaft, started in 1911, reached the deeper Flockton and Silkstone seams, which were in production by 1915. Ponies and an endless rope system were used to move coal underground.[4]

Two winding houses were built to house electric winding engines, the first in the country, from Langmeyer (subsequently AEG). Power was supplied from Yorkshire Electric’s power stations at Thornhill and Barugh (Barnsley). As the colliery was in a rural area, the company built houses in Ledston and bungalows near the pit for the manager and undermanager.[4]

The company employed 1364 men underground and 125 surface workers in 1915. The Flockton seam was abandoned in 1924 and new leases were obtained, also from Wheler; the Silkstone seam was abandoned in 1932. Beeston seam coal was wound to the surface at Peckfield via a drift. Beeston, Flockton and Silkstone coal was leased from the Earl of Lonsborough in 1933.[4]

A new company, Ledston Limited was incorporated in 1936 and it acquired the Micklefield Coal and Lime Co. Henry Briggs bought Ledston Luck and Peckfield in 1937, and the company was amalgamated with Briggs Collieries in 1939. Although Polish miners were employed at the colliery in the early years of the Second World War, Ledston was closed, and in 1943 the workforce transferred to Peckfield.[4]

When the National Coal BoardStatutory corporation created to run the coal mining industry in the United Kingdom under the Coal Industry Nationalisation Act 1946. (NCB) took over in 1947 Ledston was closed, but further reserves of coal from four deeper seams were proved in 1948, and the NCB began a project to reopen and substantially redevelop the colliery. Apart from the winding houses and No 2 headgear, the surface buildings were demolished, new headgear was provided for No 1 shaft and a 2 feet 6 inch (76 cm) gauge railway was built alongside the Ridge Road to Peckfield.[4] Pit head baths were built in 1954.[5]

The 72-inch (183 cm) Middleton seam was reached at 190 yards (174 m), where a new pit bottom was constructed and roadways driven into the seam. Underground haulage was by minecars hauled by diesel locomotives. The new pit was fully operational by 1951.[4] On the surface the minecars were taken the one and a half miles Peckfield in trains of 36 vehicles with diesel locomotives at the front and rear.[5] By mid-July 1954 the colliery employed 410 underground workers and 98 on the surface, producing 330,000 tons of coal. In 1967, 275 men were employed underground and 15 on the surface. The seams worked were the Middleton Little, Silkstone and Flockton Thick. The colliery was connected underground to Allerton Bywater’s upcast shaft for Peckfield closed in egress, as the connection to Peckfield was in poor condition. In 1971, 419 men produced 330,000 tons of coal from the Middleton Little and Flockton seams.[5]

More improvements were made underground in the 1970s and by 1979 the workings were two and a half miles (4 km) from the shafts.[6] Peckfield closed in 1980 and coal washing facilities had to be built at Ledston. The workforce of about 400 constantly averaged 300,000 tons of coal per annum, and the colliery was in profit for all but two years until 1976. The colliery closed in October 1986 and many men transferred to the Selby pits or were made redundant. The shafts were filled and capped by 1989 and some of the surface buildings had a new lease of life as Ledston Luck Enterprise Park.[6] The winding houses were listed by English Heritage, and part of the site was rewilded as a nature reserve.